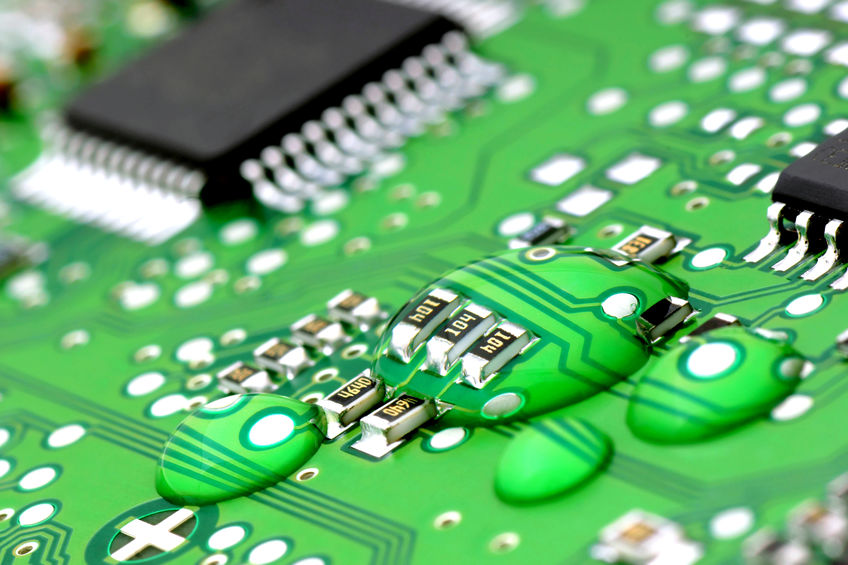

The PCB fabrication process is essential in the world of electronics. Nowadays, every company looking for PCB services wants to ensure that they are working with the best in the industry. So what is the PCB fabrication process?

The PCB fabrication refers to transcribing a circuit board onto other structures based on the design specifications. The physical transformation of circuit boards is achieved through several steps, which include:

- Imaging of the intended layout on laminates

- Removing excess copper from the inner layers to reveal pads and traces

- Creating the PCB layer stack through laminating board materials at high temperatures

- Drilling mounting holes

- Plating pinholes

- Printing polarity indicators and other necessary markings on the surface

Understanding the PCB process is essential as it will assist when it comes to hiring the best PCB manufacturer.

Choosing the Best PCB Manufacture

Without a quality printed circuit board, the electronic assembly is incomplete. One of the ways to ensure that your electronic assembling process is successful is by working with the best PCB manufacturer in the industry. But how do you ensure that you hire a reliable company? There are several factors that you will need to consider.

The Expertise in the Industry

One way to identify the capability of a PCB manufacturer to serve you right is to look at their expertise in the industry. Although many PCB manufacturers would want to create the impression that they are the best, not many are always genuine with the information they share. Therefore, it is imperative to closely examine a company’s capabilities, equipment, facilities, and human resources before you hire them. Additionally, reading the online reviews written by third parties can give you a clear picture of the capabilities of the PCB to serve your interest.

Certifications and Quality

The quality of your PCB is one of the factors that will influence your success. Therefore, it is wise to ensure that you work with a manufacturer with a proven track record in producing quality products. You do not have to first work with the company to tell whether or not their quality is the right one for you. Instead, you can check out how they handle their tasks and the processes they follow. In other words, before you start looking for a PCB manufacturer, you need to be familiar with the PCB fabrication process. Never forget to verify the company’s certifications before you start working with them.

On-time Delivery

It is also essential to check on the ability of the PCB manufacturer to deliver on time. In business, wasting a few seconds can result in substantial monetary losses. The delivery time and the quality should go in hand. One way to find out if the company you want to hire is capable of timely delivery is by looking at what other clients are saying about the company. Additionally, a time-sensitive PCB manufacturer should offer excellent customer service.

The Cost

Lastly, you need to work with a company that will not be after exploiting you financially. Besides, several PCB manufacturers can provide quality services at a pocket-friendly price. Always compare the prices of different companies before you can settle on a specific one. However, the price factor should never obscure you from hiring the best PCB manufacturer.

Looking for cheap pcb fabrication? Click the link today.

Adam Smith Anderson is a PCB design educator and advocate for diversity and inclusion in the electronics industry. Read More at PCB Manufacturer